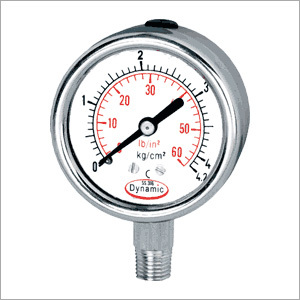

Stainless Steel Liquid Filling Gauges

Stainless Steel Liquid Filling Gauges Specification

- Display

- Analog

- Thread

- 1/8 BSP, 1/4 BSP, 1/2 BSP

- Outer Size

- 63 mm, 100 mm, 150 mm

- Seal Material

- Neoprene / PTFE / NBR

- Bourdon Tube

- Stainless Steel

- Grade

- SS304 / SS316

- Sensor Type

- Bourdon Tube

- Material

- Stainless Steel

- Dial Material

- Aluminum/SS

- Pointer Material

- Aluminum/SS

- Processing Type

- Precision Machined

- Diameter

- 63 mm / 100 mm / 150 mm

- Glass Size

- As per Outer Size

- Mount Type

- Bottom/Back/Panel Mount

- Scale Range

- 0-1 kg/cm to 0-1000 kg/cm

- Accuracy

- 1% of FSD

- Finishing

- Polished Stainless Steel

- Measure Pressure Of

- Liquids & Gases

- Accessories

- Glycerin or Silicon Oil Filled

- Case Material

- Stainless Steel 304/316

- Window

- Safety Glass / Polycarbonate

- Filling Medium

- Glycerine / Silicon Oil

- Maximum Working Pressure

- Up to 1000 kg/cm²

- Standard Followed

- EN 837-1

- Protection Grade

- IP65

- Connection

- Bottom / Back / Panel Mounting

- Application

- Chemical, Petrochemical, Food Industry, Pharmaceutical, Hydraulic Equipment

- Movement

- Stainless Steel

- Vibration Resistance

- High (due to filling)

- Operating Temperature Range

- -20°C to +65°C

Stainless Steel Liquid Filling Gauges Trade Information

- Minimum Order Quantity

- 25 Number

- Supply Ability

- 100 Per Week

- Delivery Time

- 10-15 Days

About Stainless Steel Liquid Filling Gauges

With sincere efforts to lead in international market, we have been affianced in manufacturing, exporting and supplying the best quality Stainless Steel Liquid Filling. Our offered filling is manufactured with the use of premium quality stainless steel and contemporary techniques under the guidance of our diligent professionals. This filling case is used for holding pressure gauge in order to protect its internal parts from vibration. Clients can avail this Stainless Steel Liquid Filling at market leading rates from us.

Features:

- Compact and handy

- Robust construction

- High durability

- Excellent finish

Exceptional Durability & Versatility

Manufactured from polished SS304 or SS316 stainless steel, these gauges are designed to withstand corrosive environments and high-pressure demands. The choice of safety glass or polycarbonate window enhances mechanical strength and clarity, making them suitable for harsh industrial locations. Mounting options and thread types (BSP) accommodate a variety of installation requirements across numerous industries.

Precision & Vibration Resistance

Equipped with a Bourdon tube sensor and filled with glycerine or silicon oil, these gauges minimize pointer oscillation, ensuring stable and accurate readings, even in applications with high vibrations. This design guarantees accuracy within 1% of full-scale, matched with reliable performance for sensitive processes.

FAQs of Stainless Steel Liquid Filling Gauges:

Q: How do stainless steel liquid filling gauges function in high-vibration environments?

A: These gauges are filled with glycerine or silicon oil, which dampens internal vibrations and reduces pointer flutter. This design ensures accurate, stable pressure readings and extends the operational lifespan, even in machinery or pipelines subject to continuous vibrations.Q: What industries can benefit most from using these stainless steel gauges?

A: Our gauges are engineered for chemical, petrochemical, food processing, pharmaceutical, and hydraulic equipment industries. Their corrosion-resistant construction, precision output, and compliance with EN 837-1 standards make them ideal for environments requiring reliable, hygienic, and precise pressure measurement.Q: When should I choose SS304 versus SS316 construction for my application?

A: SS304 is suitable for general industrial use where corrosion is moderate, while SS316 is preferred for more aggressive environments involving higher corrosion risks, such as in chemical processing or marine applications. Your selection should match the fluid properties and operational conditions.Q: Where can these gauges be installed and what mounting options are available?

A: The gauges support bottom, back, or panel mounting, accommodating a variety of system layouts. They can be installed on pipelines, tanks, or panels in manufacturing facilities, laboratories, or hydraulic systems, offering flexibility to match specific operational needs.Q: What is the maximum working pressure and scale range of these pressure gauges?

A: Our gauges support pressure measurements up to 1000 kg/cm, with scale ranges starting from as low as 0-1 kg/cm. This allows for precise monitoring of both low-pressure and high-pressure applications in demanding industrial environments.Q: What benefits does the IP65 protection grade offer?

A: An IP65 rating signifies that the gauge is dust-tight and protected against water jets, making it suitable for use in washdown areas, humid environments, and locations where exposure to dust or splashing liquids is anticipated.Q: How does the filling medium (glycerine or silicon oil) affect gauge performance?

A: Both glycerine and silicon oil fillings are used to dampen vibrations. Glycerine is commonly chosen for standard industrial applications, while silicon oil is better for low-temperature settings. Both options enhance long-term accuracy and protect internal components from shock.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pressure Gauges Category

Diaphragm Sealed Gauges

Minimum Order Quantity : 25

Accessories : Mounting Clamp, Rubber Gasket

Dial Material : Other, Aluminum (White Coated)

Accuracy : 1.6% FSD

Outer Size : 100 mm

Bourdon Tube : Stainless Steel

Weather Proof Gauges

Minimum Order Quantity : 25

Accessories : Rubber Gasket, Mounting Bracket

Dial Material : Other, Aluminum

Accuracy : 2% of FSD

Outer Size : 100 mm / 150 mm

Bourdon Tube : Phosphor Bronze / Stainless Steel

Pure Weather Proof Gauges

Minimum Order Quantity : 25

Accessories : Weather Proof Cover

Dial Material : Other, Aluminum with White Background

Accuracy : 1.6% FSD

Outer Size : Standard

Bourdon Tube : Stainless Steel

Differential Gauges

Minimum Order Quantity : 25

Accessories : Mounting brackets, panel mounting kit (optional)

Dial Material : Other, Aluminium (white painted with black marking)

Accuracy : 1.6% of F.S.

Outer Size : 100 mm, 150 mm

Bourdon Tube : Phosphor Bronze

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS