Differential Gauges

Differential Gauges Specification

- Bourdon Tube

- Phosphor Bronze

- Outer Size

- 100 mm, 150 mm

- Sensor Type

- Mechanical

- Grade

- Industrial

- Display

- Analog

- Thread

- 1/4 BSP (Other threads available on request)

- Seal Material

- Nitrile Rubber

- Material

- Stainless Steel (SS304/SS316) casing

- Dial Material

- Aluminium (white painted with black marking)

- Pointer Material

- Aluminium (black painted)

- Processing Type

- Calibrated for differential pressure measurement

- Diameter

- 100 mm / 150 mm

- Glass Size

- Full View Toughened Glass

- Mount Type

- Surface, Panel, Flush Mounting

- Scale Range

- 0-250 mmWC (other ranges available as per request)

- Accuracy

- 1.6% of F.S.

- Finishing

- Weatherproof, powder coated or chrome plated

- Measure Pressure Of

- Air, Gas, Non-corrosive Fluids

- Accessories

- Mounting brackets, panel mounting kit (optional)

- Max Working Pressure

- Up to 10 bar

- Applications

- Clean rooms, HVAC, process industries, filter monitoring

- Overrange Protection

- Up to 130% of full scale

- Connection Location

- Back / Bottom

- Movement

- Stainless Steel

- Window Material

- Acrylic / Toughened Glass

- Protection Class

- IP55

- Zero Adjustment

- Provided externally

- Operating Temperature Range

- -20C to +60C

Differential Gauges Trade Information

- Minimum Order Quantity

- 25 Number

- Supply Ability

- 100 Per Week

- Delivery Time

- 10-15 Days

About Differential Gauges

Our firm takes the opportunity to represent ourselves as one of the well known and foremost manufacturers, exporters and suppliers of Differential Gauges in the overseas market. Manufactured using excellent grade materials & components at the vendors end, our range is in compliance with industry quality standards. These Differential Gauges are the ideal equipments for measuring pressure difference of two different ports and indicate the difference on the dial.

Features

- High tolerance level

- Rigid construction

- Smooth finish

Robust Design for Accurate Measurement

Built with high-quality stainless steel casing and movement, this differential gauge excels in challenging industrial environments. Its IP55 weatherproof rating and powder-coated or chrome-plated finish ensure long-term reliability, while the toughened glass or acrylic window provides lasting clarity and safety during use.

Versatile Mounting and Connection Options

The gauge is engineered for flexibility with surface, panel, or flush mounting alternatives and both back and bottom connection locations. Threaded 1/4 BSP connections (with other threads available) and optional mounting brackets or panel kits simplify integration into diverse application setups.

Precision and Safety in Operation

Calibrated specifically for differential pressure measurement, this instrument features an analog display with white-painted aluminium dial and black pointer for clear readability. Overrange protection up to 130% of full scale and external zero adjustment add layers of safety and accuracy to your operations.

FAQs of Differential Gauges:

Q: How do I install the differential gauge for best performance?

A: For optimal results, select the appropriate mounting methodsurface, panel, or flushaccording to your facilitys requirements. Utilize the back or bottom connection based on your piping layout, and ensure accessories like mounting brackets or panel mounting kits, if required, are secured. Proper installation aids in sustaining accuracy and prolonging gauge life.Q: What applications is this differential gauge ideally suited for?

A: This gauge is purpose-built for clean rooms, HVAC systems, process industries, and filter monitoring. Its rugged design and precise calibration make it reliable for monitoring differential pressure in applications involving air, gas, or other non-corrosive fluids.Q: When should I adjust the zero setting on the gauge?

A: You should perform external zero adjustment when you notice any deviation from zero under no pressure condition. This external feature allows for on-site calibration, ensuring measurement reliability without dismantling the gauge.Q: Where can I use this gauge considering its protection class and temperature range?

A: Given its IP55 protection and operating temperature range of -20C to +60C, the gauge is suitable for both indoor and moderately harsh or dusty environments, providing robust performance in various industrial settings.Q: What is the process behind its precise differential pressure measurement?

A: Utilizing a mechanical sensor with a Bourdon tube made from phosphor bronze, the system translates differential pressure into pointer movement on an analog dial, calibrated to offer high accuracy (1.6% F.S.) across specified scale ranges.Q: What are the key benefits of using this differential gauge in industrial applications?

A: Key benefits include ease of installation, weatherproof construction, externally accessible calibration, broad compatibility with process connections, and reliable performance for safety-critical measurement needs. The durable construction ensures longevity and minimal maintenance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pressure Gauges Category

Process Gauges Series 900

Minimum Order Quantity : 25

Seal Material : Neoprene or Nitrile Rubber

Thread : 1/2 NPT (Others on Request)

Display : Analog

Pointer Material : Other, MicroZinc, Black

Finishing : Other, Polished Stainless Steel

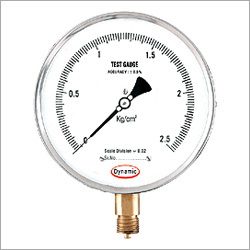

Test Gauges

Minimum Order Quantity : 25

Seal Material : Neoprene

Thread : 1/2 BSP

Display : Analog

Pointer Material : Other, Alloy Steel

Finishing : Other, Polished Chrome

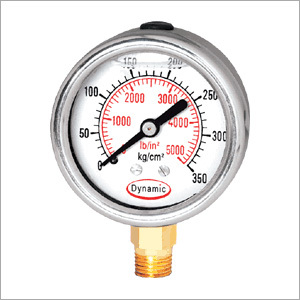

Liquid Filling SS Case Gauges

Minimum Order Quantity : 25

Seal Material : Nitrile Rubber / Neoprene

Thread : 1/2 BSP or NPT

Display : Analog

Pointer Material : Other, Black Painted Aluminium

Finishing : Other, Polished SS

Diaphragm Pressure Gauges

Minimum Order Quantity : 25

Seal Material : PTFE / Neoprene / Viton

Thread : 1/2 BSP (customizable)

Display : Analog

Pointer Material : Other, Black painted aluminum

Finishing : Other, Matt / Polished

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS