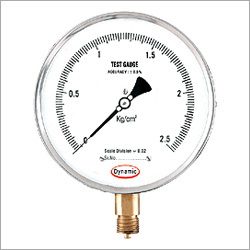

Test Gauges

Test Gauges Specification

- Outer Size

- 125 mm

- Display

- Analog

- Grade

- Industrial

- Sensor Type

- Mechanical

- Seal Material

- Neoprene

- Bourdon Tube

- Phosphor Bronze

- Thread

- 1/2 BSP

- Material

- Stainless Steel Casing

- Dial Material

- Aluminium

- Pointer Material

- Alloy Steel

- Processing Type

- Cold-Drawn

- Diameter

- 125 mm

- Glass Size

- 120 mm

- Mount Type

- Bottom Connection

- Scale Range

- 0 to 7 kg/cm

- Accuracy

- 1% of full scale

- Finishing

- Polished Chrome

- Measure Pressure Of

- Liquid & Gas

- Accessories

- Rubber Gasket, Protective Cover

- IP Rating

- IP55

- Over Range Protection

- 130% of FSD

- Pressure Element

- Bourdon type

- Back Flange

- Available on demand

- Application

- Calibration, Testing, Industrial Measurements

- Connection Type

- Bottom entry

- Case Material

- Stainless Steel 304

- Window Type

- Toughened Glass

- Service

- Suitable for air, oil, water and non-corrosive gases and liquids

- Movement Material

- Brass

- Operating Temperature

- -10°C to +60°C

- Scale Marking

- Black on White

Test Gauges Trade Information

- Minimum Order Quantity

- 25 Number

- Supply Ability

- 100 Per Week

- Delivery Time

- 10-15 Days

About Test Gauges

With the aid of our widespread manufacturing unit and distribution network, we are proficient in manufacturing and exporting an outstanding array of Test Gauges to our esteemed patrons. Extensively demanded in laboratories for testing and inspection of other gauges as well as for high accuracy measurement, our offered gauges are well appreciated for their excellent durability and wide usage. These Test Gauges are available in various models as per the clients' requirements.

Features

- Accurate

- Rugged construction

- Corrosion resistant

Premium Stainless Steel Construction

The casing is manufactured from Stainless Steel 304, ensuring optimal corrosion resistance and long-lasting performance, especially in challenging industrial settings. The polished chrome finish and cold-drawn processing enhance both durability and aesthetic appeal, while also providing added protection for the internal mechanisms.

Versatile Application and Reliable Performance

Designed for calibration, testing, and various industrial measurements, this test gauge is ideal for use with air, oil, water, and non-corrosive gases and liquids. Its Bourdon tube technology, combined with a mechanical sensor system, delivers precise analog readings for critical pressure monitoring tasks.

Enhanced Safety and User-Convenience Features

The gauge is equipped with over-range protection (up to 130% of Full Scale Deflection) and an IP55 rating, offering substantial protection against dust and water. The toughened glass window and sturdy back flange (available on demand) add safety, while the scale markings ensure easy readability during operation.

FAQs of Test Gauges:

Q: How should I install the Test Gauge with a bottom entry connection?

A: Install the test gauge using the 1/2 BSP bottom entry thread, ensuring it is securely tightened and sealed with the provided rubber gasket. Mount it vertically for optimal accuracy and visibility, and use the back flange if additional support is required (available on demand).Q: What materials are used in the construction of this test gauge?

A: The gauge features a Stainless Steel 304 casing, phosphor bronze Bourdon tube, brass movement, toughened glass window, neoprene seal, aluminium dial, and alloy steel pointer. These materials offer robust performance and resistance to corrosion for industrial applications.Q: When should I consider using this test gauge for my applications?

A: Use this test gauge for calibration, testing, or routine measurement of pressure in systems handling air, oil, water, or non-corrosive gases and liquids, especially where accuracy and durability are critical within the 0 to 7 kg/cm range.Q: Where is this test gauge best suited for operation?

A: It is ideal for installation in laboratories, industrial plants, service workshops, and calibration facilities in environments with an operating temperature between -10C to +60C. Its IP55 rating ensures suitability in both moderately wet and dusty locations.Q: What is the accuracy and measurement range of this gauge?

A: The gauge provides a measurement range from 0 to 7 kg/cm with an accuracy of 1% of the full scale, ensuring precise readings for most industrial and calibration needs.Q: How does the over-range protection feature benefit users?

A: With protection up to 130% of full scale deflection, the gauge can safely withstand accidental pressure surges beyond its specified range, minimizing the risk of damage and extending instrument life.Q: What accessories are included with this test gauge?

A: The gauge comes with a rubber gasket for sealing, a protective cover for added durability, and offers a back flange on demand for specialized mounting requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pressure Gauges Category

Diaphragm Sealed Gauges

Minimum Order Quantity : 25

Dial Material : Other, Aluminum (White Coated)

Sensor Type : Bourdon Tube

Seal Material : PTFE / SS

Diameter : 100 mm

Grade : Industrial Grade

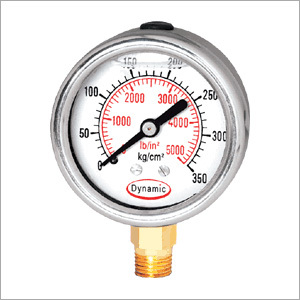

Liquid Filling SS Case Gauges

Minimum Order Quantity : 25

Dial Material : Other, Aluminium with White Powder Coating

Sensor Type : Mechanical

Seal Material : Nitrile Rubber / Neoprene

Diameter : 100 mm, 150 mm

Grade : Industrial Grade

Differential Gauges

Minimum Order Quantity : 25

Dial Material : Other, Aluminium (white painted with black marking)

Sensor Type : Mechanical

Seal Material : Nitrile Rubber

Diameter : 100 mm / 150 mm

Grade : Industrial

Diaphragm Pressure Gauges

Minimum Order Quantity : 25

Dial Material : Other, Aluminum with white background

Sensor Type : Diaphragm Sensor

Seal Material : PTFE / Neoprene / Viton

Diameter : 150 mm

Grade : Industrial Grade

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS