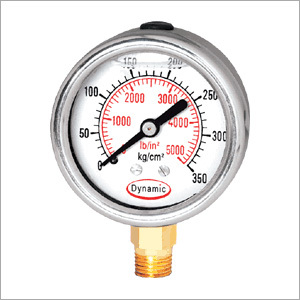

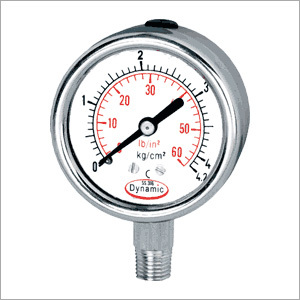

Liquid Filling SS Case Gauges

Liquid Filling SS Case Gauges Specification

- Sensor Type

- Mechanical

- Thread

- 1/2 BSP or NPT

- Bourdon Tube

- Stainless Steel

- Seal Material

- Nitrile Rubber / Neoprene

- Display

- Analog

- Outer Size

- 100 mm, 150 mm

- Grade

- Industrial Grade

- Material

- Stainless Steel (SS 304/316)

- Dial Material

- Aluminium with White Powder Coating

- Pointer Material

- Black Painted Aluminium

- Processing Type

- Liquid Filled

- Diameter

- 100 mm, 150 mm

- Glass Size

- Full Front

- Mount Type

- Bottom or Back

- Scale Range

- 0 to 16 Bar / 0 to 250 Psi

- Accuracy

- +/- 1% of FSD

- Finishing

- Polished SS

- Measure Pressure Of

- Liquids & Gases

- Accessories

- Mounting Flange, Rubber Gasket

- Application

- Chemical, Petrochemical, Pharmaceutical, Food Processing, Oil & Gas Industries

- Filling Medium

- Glycerin or Silicon Oil

- Protection Class

- IP 65

- Over Pressure Limit

- 130% of Full Scale

- Mount Orientation

- Vertical / Horizontal

- Case Design

- Hermetically Sealed Liquid Filled

- Window Material

- Acrylic / Toughened Glass

- Connecting Type

- Threaded

- Operating Temperature

- -20°C to +65°C

- Movement Material

- Brass / SS

Liquid Filling SS Case Gauges Trade Information

- Minimum Order Quantity

- 25 Number

- Supply Ability

- 100 Per Week

- Delivery Time

- 10-15 Days

About Liquid Filling SS Case Gauges

We have been affianced in manufacturing, exporting and supplying an extensive array of Liquid Filling S S Case. Our offered case is suitable where pressure gauges are installed to severe conditions. Filled liquid in this case protects internal parts against vibrations. The provided case is manufactured under the supervision of our dexterous professionals with the use of supreme quality stainless steel and cutting-edge techniques. Besides, our patrons can avail this Liquid Filling S S Case at pocket friendly prices from us.

Features:

- Precise functioning

- Automatic operations

- High sensitivity

- Longer service life

Superior Design and Materials

These gauges are constructed from top-grade stainless steel (SS 304/316) with a polished finish, ensuring corrosion resistance and durability. The hermetically sealed and liquid-filled case, combined with an acrylic or toughened glass window, maximizes product life and consistent performance in harsh industrial environments.

Precision and Versatility

With a bourdon tube sensor and analog display, the gauge accurately measures liquid and gas pressures up to 16 bar or 250 Psi. Accuracy within +/-1% of full scale deflection meets the highest industrial standards. It supports both bottom and back mounting, adapting to different pipeline setups.

Designed for Tough Environments

Certified to IP65 and equipped with Nitrile Rubber or Neoprene seals, these gauges withstand dust, water, and overpressure conditions up to 130% of full scale. Glycerin or silicone oil filling dampens vibrations and sudden pressure changes, making them suitable for high-vibration and hazardous areas.

FAQs of Liquid Filling SS Case Gauges:

Q: How does a liquid-filled SS case gauge improve pressure measurement in industrial applications?

A: A liquid-filled SS case gauge absorbs pressure spikes and vibrations using a glycerin or silicon oil medium. This enhances measurement stability and gauge longevity, making it ideal for process industries such as chemical, petrochemical, and food processing.Q: What types of media can these gauges safely measure?

A: These gauges are compatible with a range of non-corrosive and corrosive liquids and gases, thanks to their stainless steel (SS 304/316) construction, suitable sealing materials, and aluminium dials.Q: When should you use a hermetically sealed liquid-filled gauge?

A: Hermetically sealed liquid-filled gauges should be used in environments with high vibration, pulsation, or where accidental ingress of contaminants could occursuch as oil & gas facilities, chemical plants, or food processing sites.Q: Where are these gauges typically installed in a process system?

A: These gauges are commonly installed at critical monitoring points on pipelines, process vessels, or reactorsanywhere accurate pressure readings of liquids or gases are essential to operational safety and efficiency.Q: What is the process for selecting the correct mounting orientation for these gauges?

A: Choose vertical or horizontal mounting based on pipeline configuration and visibility needs. Bottom mounting is standard, while back mounting is used where panel integration or space constraints require it. Accessories like mounting flanges and rubber gaskets facilitate secure installation.Q: How do users benefit from the gauges IP65 rating and robust construction?

A: The IP65 rating ensures resistance to dust and water ingress, while the polished SS construction and nitrile/neoprene seals provide durability and reduce maintenanceresulting in long-term reliability, even in harsh industrial settings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pressure Gauges Category

Commercial Utility Gauges

Minimum Order Quantity : 25

Accuracy : 1.6% FSD

Sensor Type : Bourdon Tube

Thread : 1/4 BSP

Finishing : Other, Powder Coated

Diameter : 63 mm

Process Gauges Series 900

Minimum Order Quantity : 25

Accuracy : 1% of FSD

Sensor Type : Bourdon Tube

Thread : 1/2 NPT (Others on Request)

Finishing : Other, Polished Stainless Steel

Diameter : 100 mm, 150 mm

Precision Test Gauges

Minimum Order Quantity : 25

Accuracy : 0.25% FSD

Sensor Type : Mechanical

Thread : 1/2 BSP

Finishing : Other, Chrome Plated

Diameter : 150 mm

Stainless Steel Liquid Filling Gauges

Minimum Order Quantity : 25

Accuracy : 1% of FSD

Sensor Type : Bourdon Tube

Thread : 1/8 BSP, 1/4 BSP, 1/2 BSP

Finishing : Other, Polished Stainless Steel

Diameter : 63 mm / 100 mm / 150 mm

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS