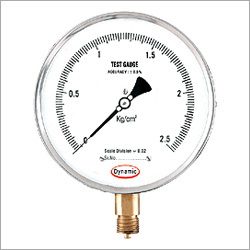

Precision Test Gauges

Precision Test Gauges Specification

- Outer Size

- 150 mm

- Sensor Type

- Mechanical

- Grade

- Industrial Grade

- Bourdon Tube

- Phosphor Bronze

- Thread

- 1/2 BSP

- Display

- Analog

- Seal Material

- Neoprene Rubber

- Material

- Stainless Steel

- Dial Material

- Aluminum

- Pointer Material

- Black Painted Aluminum

- Processing Type

- Calibrated

- Diameter

- 150 mm

- Glass Size

- 145 mm

- Mount Type

- Bottom Connection

- Scale Range

- 0 to 7 kg/cm

- Accuracy

- 0.25% FSD

- Finishing

- Chrome Plated

- Measure Pressure Of

- Gas and Liquid

- Accessories

- Carrying Case, Calibration Certificate

- Calibration Interval

- Recommended Annually

- Ambient Temperature

- -20°C to +60°C

- Connection Location

- Lower/BSP

- Pointer Type

- Knife Edge

- Protection Class

- IP65

- Window Type

- Shatterproof Plexiglass

- Zero Adjustment

- External

- Application

- Calibration Laboratories, Testing Industries

- Packing Type

- Individual Box

- Case Material

- Drawn Steel Black Enamel

- Weight

- Approx. 1.2 kg

- Overload Capacity

- Up to 130% of FSD

- Movement

- Precision Brass

Precision Test Gauges Trade Information

- Minimum Order Quantity

- 25 Number

- Supply Ability

- 100 Per Week

- Delivery Time

- 10-15 Days

About Precision Test Gauges

Owing to our years of expertise in this pressure gauges, we are manufacturing and exporting a commendable range of Precision Test Gauges. Designed using superior quality raw materials and utilizing advanced technology, these gauges ensure maintenance free working as well as longer service life. Widely used for gases and liquid media for testing & calibration in laboratories, these Precision Test Gauges are available in various specifications.

Features

- Accurate reading

- Durable

- Precise result

Robust Construction for Demanding Applications

These test gauges are constructed using a steel case with chrome plating, shatterproof plexiglass windows, and precision brass movement. Their IP65 protection ensures resilience against dust and moisture, making them suitable for industrial and laboratory settings. The neoprene rubber seal and calibrated processing offer enhanced durability and performance.

Exceptional Accuracy and Clear Display

With a scale range of 0 to 7 kg/cm and an accuracy of 0.25% of full-scale deflection, these gauges deliver consistently reliable readings. The analog display features a 150 mm diameter dial, 145 mm glass size, and a clear, easily visible knife-edge pointer for pinpoint precision.

User-Friendly and Certified

These gauges offer external zero adjustment for quick recalibration and are supplied with a calibration certificate. Their individual box packing and included carrying case facilitate secure handling, making them suitable for both on-site and laboratory use.

FAQs of Precision Test Gauges:

Q: How do I install and connect the Precision Test Gauge?

A: The gauge features a 1/2 BSP bottom connection, which should be securely attached to the compatible pressure line. Ensure a proper seal with the provided neoprene rubber gasket and mount the unit vertically for optimal accuracy.Q: What applications are these gauges most suitable for?

A: These gauges are ideal for calibration laboratories and industrial testing environments. They are designed to measure the pressure of gases and liquids with high accuracy, making them suitable for both quality control and process monitoring.Q: When should the gauge be calibrated or serviced?

A: We recommend calibrating the gauge annually to maintain its high accuracy, as indicated by the provided calibration certificate and in accordance with industry standards.Q: Where can I use these test gauges safely?

A: With an IP65 protection class, the gauges can be used in environments exposed to dust and moisture, such as industrial workshops, laboratories, and manufacturing units. Ensure operation within the specified temperature range of -20C to +60C for reliable performance.Q: What benefits does the shatterproof plexiglass window provide?

A: The shatterproof plexiglass window enhances safety by minimizing the risk of breakage, ensuring long-term durability and protecting users in demanding settings.Q: How do I perform zero adjustment on the gauge?

A: External zero adjustment can be made using the access feature on the front of the gauge, allowing for effortless recalibration without disassembling the unit.Q: What accessories and certifications are included with the gauge?

A: Each gauge is supplied with a carrying case for transport, along with a calibration certificate verifying its accuracy, making it convenient for professional use and compliance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pressure Gauges Category

Commercial Utility Gauges

Minimum Order Quantity : 25

Sensor Type : Bourdon Tube

Finishing : Other, Powder Coated

Outer Size : Standard

Grade : Industrial Grade

Dial Material : Other, Aluminum

Weather Proof Gauges

Minimum Order Quantity : 25

Sensor Type : Bourdon Tube

Finishing : Other, Powder Coated / Chrome Plated

Outer Size : 100 mm / 150 mm

Grade : Industrial

Dial Material : Other, Aluminum

Liquid Filling SS Case Gauges

Minimum Order Quantity : 25

Sensor Type : Mechanical

Finishing : Other, Polished SS

Outer Size : 100 mm, 150 mm

Grade : Industrial Grade

Dial Material : Other, Aluminium with White Powder Coating

Test Gauges

Minimum Order Quantity : 25

Sensor Type : Mechanical

Finishing : Other, Polished Chrome

Outer Size : 125 mm

Grade : Industrial

Dial Material : Other, Aluminium

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free