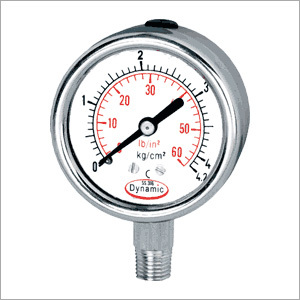

Commercial Utility Gauges

Commercial Utility Gauges Specification

- Bourdon Tube

- Phosphor Bronze

- Display

- Analog

- Grade

- Industrial Grade

- Outer Size

- Standard

- Thread

- 1/4 BSP

- Sensor Type

- Bourdon Tube

- Seal Material

- Rubber Gasket

- Material

- Stainless Steel / Brass

- Dial Material

- Aluminum

- Pointer Material

- Aluminum

- Processing Type

- Machined

- Diameter

- 63 mm

- Glass Size

- 63 mm

- Mount Type

- Bottom Connection

- Scale Range

- 0 to 300 psi

- Accuracy

- 1.6% FSD

- Finishing

- Powder Coated

- Measure Pressure Of

- Air, Gas, Liquid (Non-corrosive)

- Accessories

- Mounting Clamp

- Enclosure Protection

- IP65

- Operating Temperature

- -20°C to +60°C

- Mounting Position

- Vertical

- Case Material

- Steel

- Movement

- Brass

- Application

- Industrial Utilities, Compressors, Pumps

- Window Type

- Clear Glass

Commercial Utility Gauges Trade Information

- Minimum Order Quantity

- 25 Number

- Payment Terms

- Cheque

- Supply Ability

- 100 Per Week

- Delivery Time

- 10-15 Days

- Sample Available

- Yes

- Main Domestic Market

- All India

About Commercial Utility Gauges

Serving the varied requirements of diverse industrial sectors, we take immense pride to commence ourselves as the noteworthy manufacturer, exporter and supplier of Utility (Commercial) Gauges. The gauges offered by us are widely used for measuring air, water, and gas pressure in various hydraulic and pneumatic applications. Designed with high precision, these Utility (Commercial) Gauges are available in various specifications as per the requirement of our clients.

Features

- Accurate results

- Rugged design

- Excellent durability

Durable Build for Industrial Applications

Constructed from high-quality steel, brass, and aluminum, these gauges are engineered to withstand harsh industrial environments. The powder-coated case and IP65 rating provide exceptional protection against dust and moisture, making them ideal for continuous operation in compressor and pump systems.

Versatile Pressure Measurement

Capable of accurately measuring pressure for air, gas, and non-corrosive liquid mediums, these gauges use a phosphor bronze Bourdon tube for lasting accuracy and reliability. The analog display and standard 63 mm diameter ensure straightforward pressure monitoring across a wide scale.

Easy Installation and Maintenance

Each gauge is equipped with a 1/4 BSP bottom connection and includes a mounting clamp for secure vertical installation. The machined process and standard sizing mean that replacement or new installation is simple in most industrial settings, reducing downtime.

FAQs of Commercial Utility Gauges:

Q: How should I install the commercial utility gauge for optimal performance?

A: Install the gauge in a vertical position using the included mounting clamp and 1/4 BSP bottom connection. Ensure the environment falls within the -20C to +60C range and that the medium measured is air, gas, or non-corrosive liquid.Q: What types of media can this gauge safely measure?

A: This utility gauge is suitable for measuring the pressure of air, gas, and non-corrosive liquids within industrial equipment like compressors and pumps.Q: When is recalibration or maintenance required for the gauge?

A: Regular recalibration is recommended annually or after extended periods of heavy use to ensure the 1.6% FSD accuracy. Inspect the gauge if exposed to extreme pressure fluctuations or physical impacts.Q: Where can these gauges be installed?

A: They are designed for use in industrial environments across compressors, pumps, and other utility systems. Thanks to their IP65 rating, they can be installed indoors or in sheltered outdoor locations.Q: What benefits does the powder-coated steel case provide?

A: The powder-coated steel case enhances durability by protecting against corrosion, wear, and environmental contaminants, extending the gauges service life in harsh industrial settings.Q: How does the IP65 enclosure protection help in industrial usage?

A: IP65 protection safeguards the internal components against dust and water jets, ensuring reliable operation and longevity even in challenging conditions common to industrial utilities.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pressure Gauges Category

Differential Gauges

Minimum Order Quantity : 25

Diameter : 100 mm / 150 mm

Seal Material : Nitrile Rubber

Accuracy : 1.6% of F.S.

Dial Material : Other, Aluminium (white painted with black marking)

Scale Range : 0250 mmWC (other ranges available as per request)

Diaphragm Pressure Gauges

Minimum Order Quantity : 25

Diameter : 150 mm

Seal Material : PTFE / Neoprene / Viton

Accuracy : 1.6% FSD

Dial Material : Other, Aluminum with white background

Scale Range : 0 to 10 kg/cm (custom, up to 025 kg/cm)

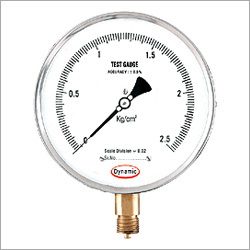

Test Gauges

Minimum Order Quantity : 25

Diameter : 125 mm

Seal Material : Neoprene

Accuracy : 1% of full scale

Dial Material : Other, Aluminium

Scale Range : 0 to 7 kg/cm

Stainless Steel Liquid Filling Gauges

Minimum Order Quantity : 25

Diameter : 63 mm / 100 mm / 150 mm

Seal Material : Neoprene / PTFE / NBR

Accuracy : 1% of FSD

Dial Material : Other, Aluminum/SS

Scale Range : 01 kg/cm to 01000 kg/cm

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS