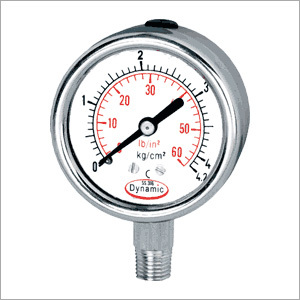

Contact Gauges

Contact Gauges Specification

- Outer Size

- 100 mm

- Thread

- 1/8 BSP

- Grade

- Industrial

- Bourdon Tube

- Copper Alloy

- Seal Material

- Synthetic Rubber

- Sensor Type

- Mechanical

- Display

- Analog

- Material

- Stainless Steel

- Dial Material

- Aluminum

- Pointer Material

- Black Painted Aluminum

- Processing Type

- Forged

- Diameter

- 100 mm

- Glass Size

- 100 mm

- Mount Type

- Bottom/Back

- Scale Range

- 0 to 7 kg/cm²

- Accuracy

- ±1.6% of FSD

- Finishing

- Powder Coated

- Measure Pressure Of

- Gas, Liquid

- Accessories

- Contact System

- Window

- Shatterproof Glass

- Zero Adjustment

- External

- Enclosure Material

- Stainless Steel 304

- Switch Rating

- 230V AC, 5A

- Contact Type

- Magnetic Electrically Operated

- Operating Temperature

- -20°C to 70°C

- Maximum Working Pressure

- 7 kg/cm²

- IP Rating

- IP54

Contact Gauges Trade Information

- Minimum Order Quantity

- 25 Number

- Supply Ability

- 100 Per Week

- Delivery Time

- 10-15 Days

About Contact Gauges

We have in-depth knowledge in the market that enables us in manufacturing, supplying and exporting a quality assured assortment of Contact Gauges. Available in different technical specification, these pressure gauges are widely used for controlling the pressure as well as for audible or visible alarms. Our offered Contact Gauges are highly demanded in market due to their reliability and are available at market leading prices.

Features

- Easy to use

- Excellent durability

- Low maintenance cost

Durable Construction for Demanding Environments

Manufactured with high-quality stainless steel 304 and finished with a powder coating, these contact gauges are built to withstand industrial conditions. The shatterproof glass window enhances safety, making it suitable for harsh environments where durability is essential. Each gauge processes pressure using a forged stainless steel body and synthetic rubber seals for longevity.

Exceptional Accuracy and Versatility

The gauge offers a wide scale range from 0 to 7 kg/cm with an accuracy of 1.6% of the full-scale deflection. Suitable for measuring both gases and liquids, it features a mechanical sensor and a copper alloy Bourdon tube, ensuring precise and reliable pressure readings under various industrial applications. Easy external zero adjustment enhances operational flexibility.

User-Friendly Features and Safety Compliance

Designed for convenience, the gauge has a clear, analog display, and options for bottom or back mounting. Its IP54 rating ensures resistance to dust and splashes, while the 230V AC, 5A switch rating supports robust electrical performance. The windows shatterproof glass and powder-coated finish guarantee additional safety and easy maintenance.

FAQs of Contact Gauges:

Q: How does the magnetic electrically operated contact gauge function?

A: The device uses a mechanical sensor with a copper alloy Bourdon tube that measures pressure changes. The integrated magnetic contact system triggers electrical switching at set pressure points, enabling automated monitoring or control in your process.Q: What are the main benefits of the stainless steel 304 enclosure for this contact gauge?

A: The stainless steel 304 enclosure provides excellent corrosion resistance, mechanical strength, and durability, making the gauge suitable for demanding industrial applications and increasing its operational lifespan.Q: Where can this contact gauge be installed in an industrial setup?

A: Thanks to its bottom or back mounting options and compact 100 mm outer size, the gauge can be easily installed in control panels, pipelines, or machinery where accurate pressure monitoring of gases and liquids is essential.Q: When should I perform external zero adjustment on the gauge?

A: Zero adjustment should be performed whenever you notice a deviation at zero pressure on the dial, after installation, or during routine calibration to ensure consistent and accurate readings.Q: What ensures the safety and reliability of the gauge in harsh environments?

A: The combination of an IP54-rated enclosure, shatterproof glass, powder-coated finish, synthetic rubber seals, and robust mechanical construction ensures reliable operation and user safety in dusty and humid industrial environments.Q: How do I benefit from the analog display and contact system in daily operations?

A: The analog display provides at-a-glance pressure readings, while the magnetic contact system automates electrical circuits when specific pressure levels are reached, helping streamline process controls and enhance operational efficiency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pressure Gauges Category

Commercial Utility Gauges

Minimum Order Quantity : 25

Finishing : Other, Powder Coated

Measure Pressure Of : Other, Air, Gas, Liquid (Noncorrosive)

Display : Analog

Diameter : 63 mm

Accuracy : ±1.6% FSD

Process Gauges Series 900

Minimum Order Quantity : 25

Finishing : Other, Polished Stainless Steel

Measure Pressure Of : Other, Liquid, Gas and Vapour

Display : Analog

Diameter : 100 mm, 150 mm

Accuracy : ±1% of FSD

Stainless Steel Liquid Filling Gauges

Minimum Order Quantity : 25

Finishing : Other, Polished Stainless Steel

Measure Pressure Of : Other, Liquids & Gases

Display : Analog

Diameter : 63 mm / 100 mm / 150 mm

Accuracy : ±1% of FSD

Differential Gauges

Minimum Order Quantity : 25

Finishing : Other, Weatherproof, powder coated or chrome plated

Measure Pressure Of : Other, Air, Gas, Noncorrosive Fluids

Display : Analog

Diameter : 100 mm / 150 mm

Accuracy : ±1.6% of F.S.

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS